Wir bedanken uns bei allen Besuchern auf der Euro Blech 2022 in Hannover!

Abkantwerkzeuge Stanz- und Umformwerkzeuge dank WESO Werkzeugbau

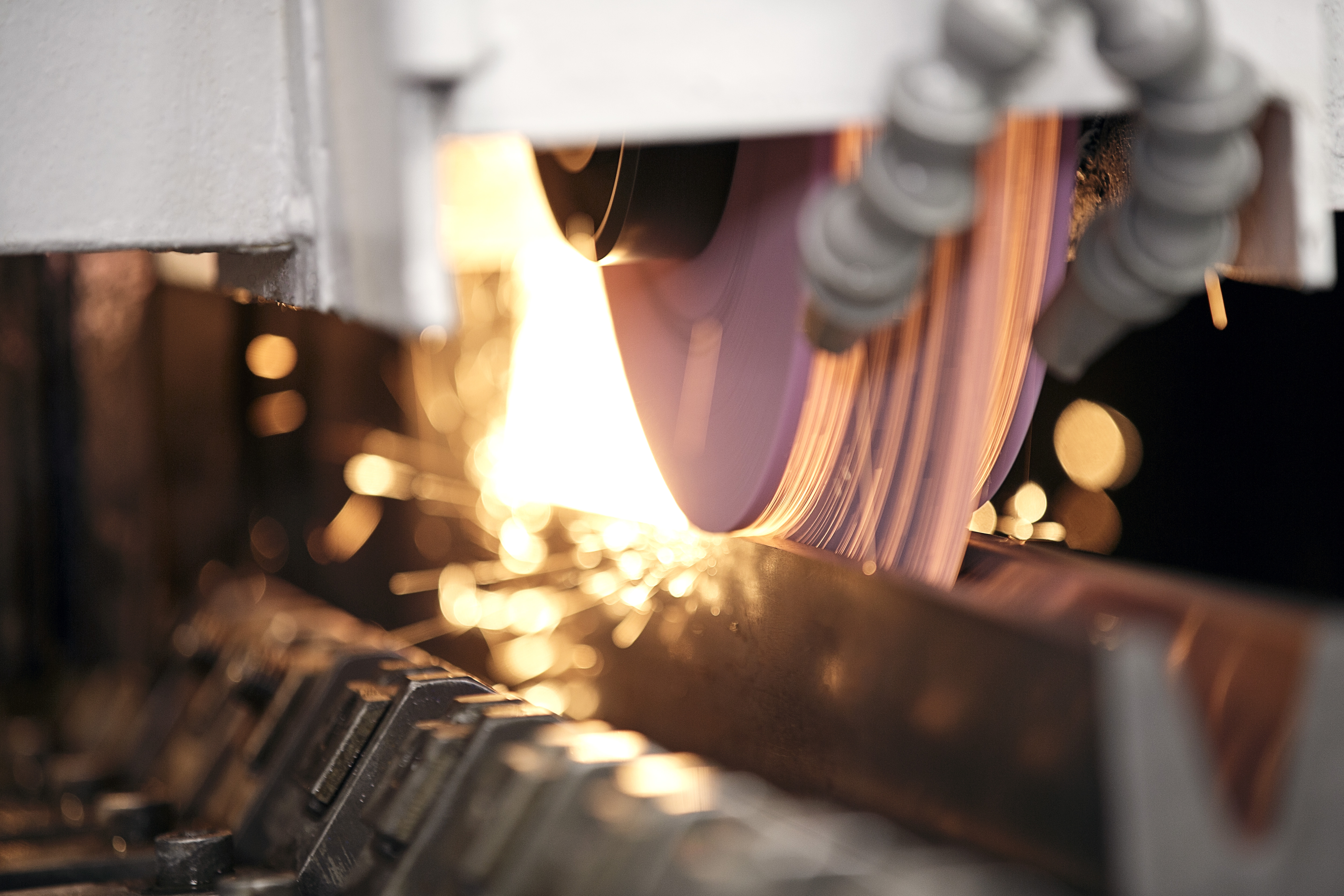

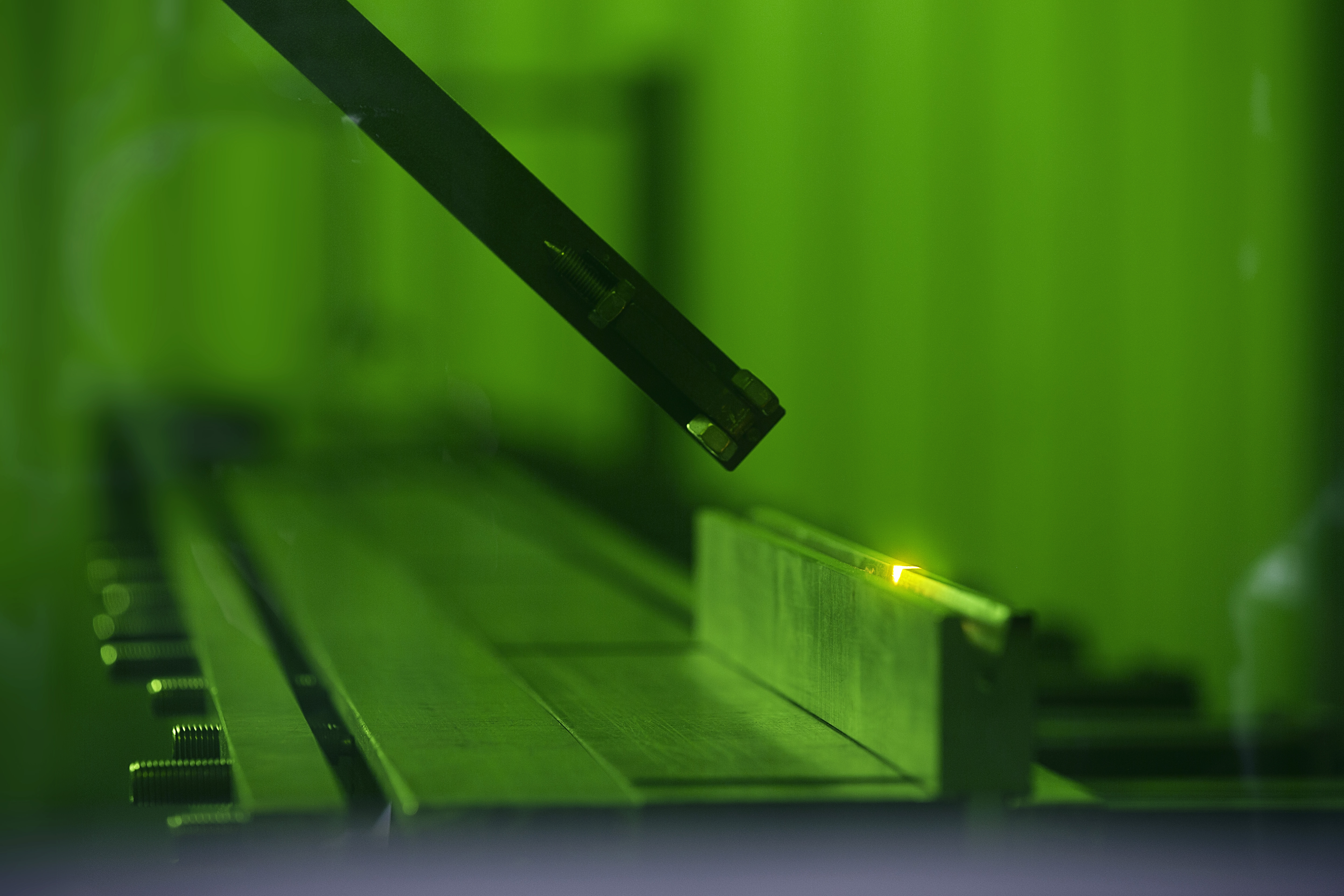

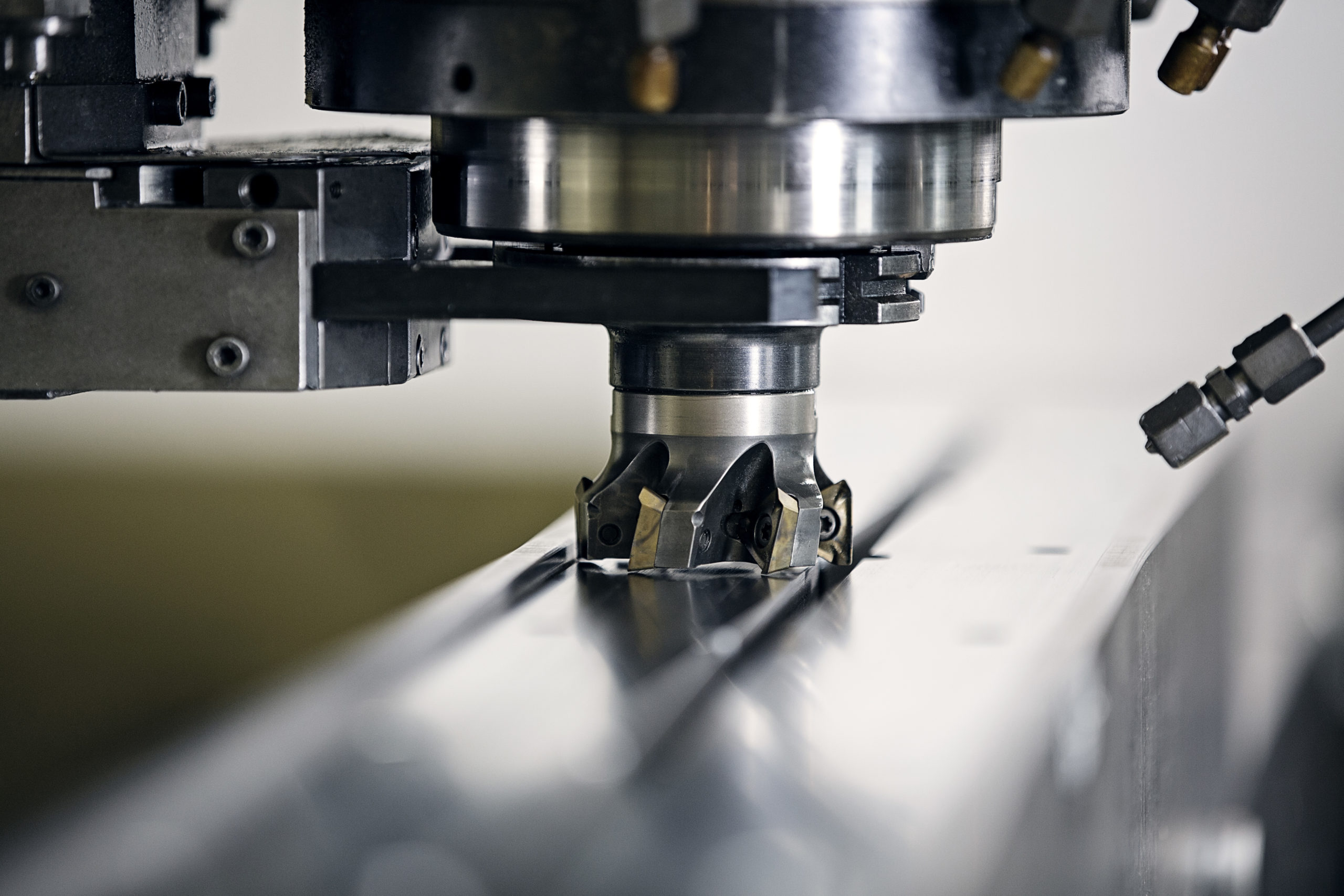

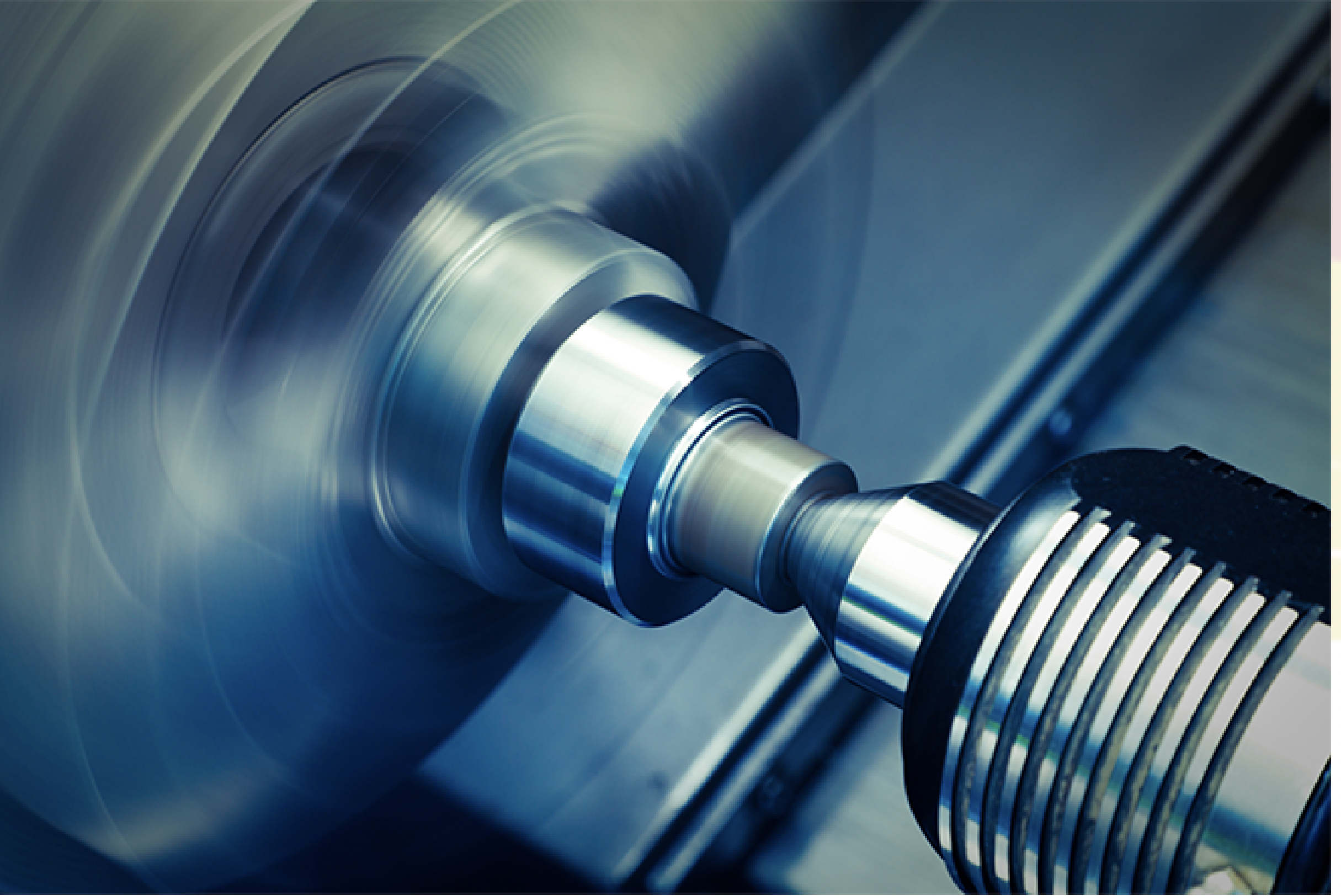

Herzlich Willkommen auf der Website der WESO Werkzeugbau GmbH. Hier finden Sie alle notwendigen Informationen zu den von uns angebotenen Produkten und Dienstleistungen. Im Jahr 1903 wurde die Westermann GmbH gegründet. Seitdem versorgen wir Sie mit unserer Expertise im Bereich der Konstruktion und Produktion von Abkantwerkzeugen, sowie mit der Bereitstellung von Schleif-Dienstleistungen. Seit Januar 2021 sind wir als WESO Werkzeugbau GmbH für Sie da und erweitern unsere Produktpalette um die Bereiche Stanz- und Umformwerkzeuge.

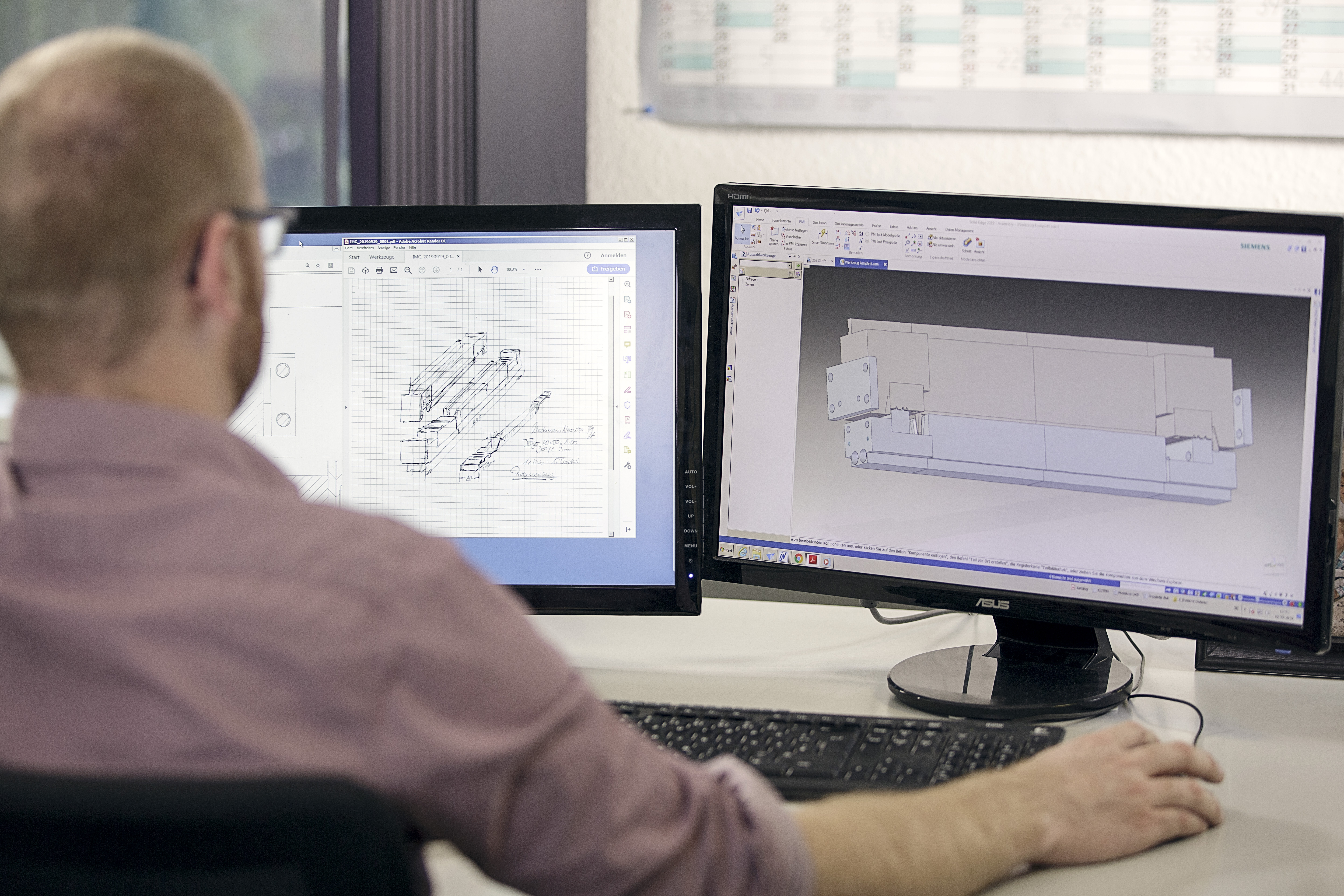

Informieren Sie sich hier ausführlich über unsere breite Produktpalette, die sowohl die Fertigung von Sonderwerkzeugen als auch von Serien- und Standardwerkzeugen umfasst. Ausschlaggebend sind für uns dabei immer die individuellen Bedürfnisse und Vorstellungen unserer Kunden, nach deren Anforderungen wir unsere Werkzeuge in kürzester Zeit konstruieren und produzieren. WESO Werkzeugbau legt dabei besonderen Wert auf Präzision, Qualität und Haltbarkeit – entdecken Sie die gesamte Bandbreite unseres Angebots hier auf unserer Website. Bei Fragen zu unseren Produkten oder sonstigen Anregungen nehmen Sie Kontakt mit uns auf. Sie finden unsere Kontaktdaten unter dem Menüpunkt Kontakt. Damit Sie einen besseren Eindruck von der Arbeit bei WESO Werkzeugbau und unseren Produkten erhalten, haben wir Ihnen hier unseren Image-Film und einige Produktvideos zur Verfügung gestellt:

Schauen Sie sich hier unseren Image-Film und unsere Produktvideos an:

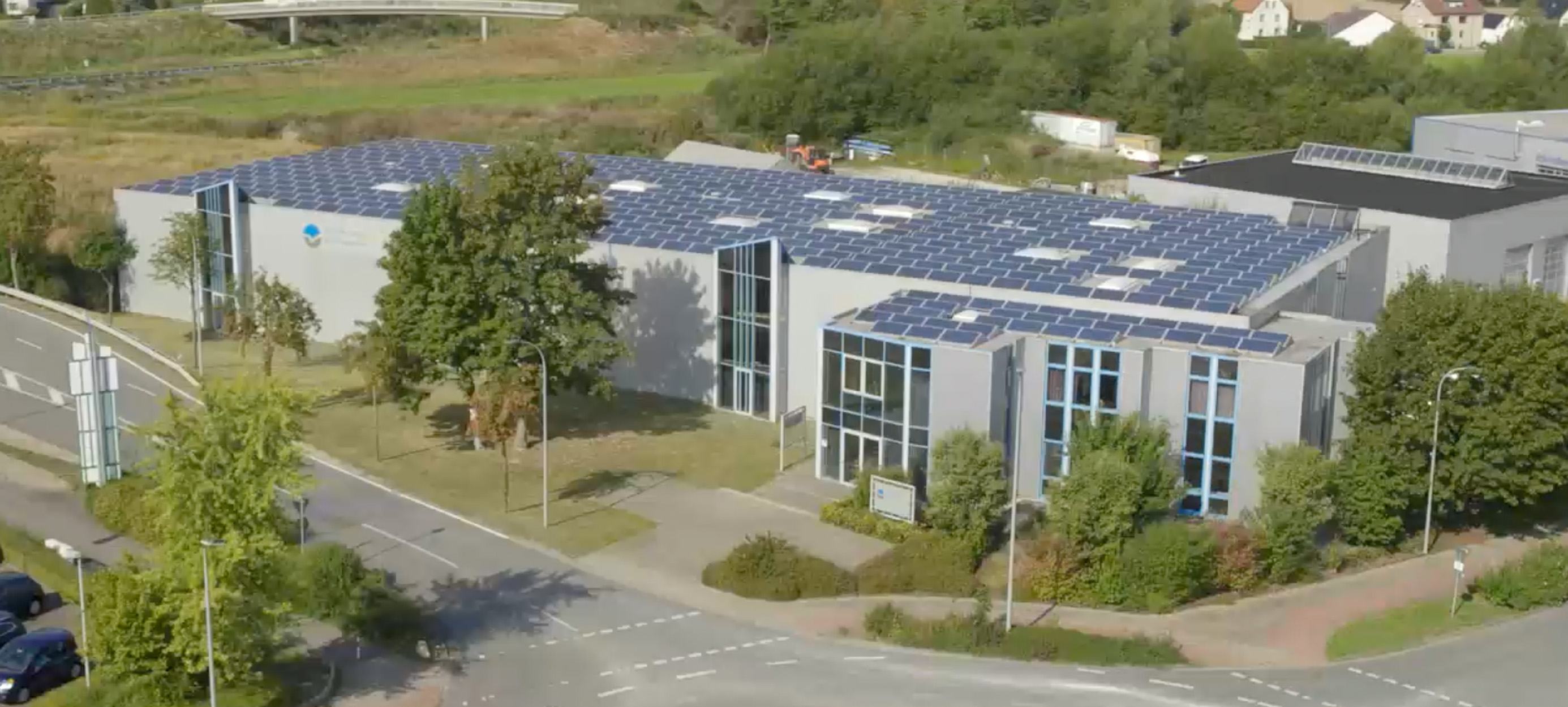

Unser Standort – WESO Werkzeugbau

Unsere Produkte – Werkzeuge von WESO Werkzeugbau

Lernen Sie die präzise Funktionsweise und die qualitativ hochwertige Fertigung unseres WESO-Stations-Folgewerkzeugs kennen. Hiermit lassen sich auf einfache Weise mehrere Kantungen hintereinander in verschiedenen Stationen herstellen. In der im Video dargestellten Variante sehen Sie beispielsweise wie an das Werkstück eine zusätzliche Nase zu einer geschlossenen Doppelfalz angekantet wird, sodass ein Nut- und Feder-System entsteht. Dieses kann zur einfachen Verbindung zweier Werkstücke aneinander genutzt werden, in der Funktionsweise mit einem Laminat-Klickboden vergleichbar. Die Werkzeughöhe des WESO-Stations-Folgewerkzeugs ist an die restlichen Stationen, die auch aus Standardwerkzeugen bestehen können, angepasst. Auch hier erhalten Sie Versuch und Werkzeugkorrektur inklusive.

Mit dem WESO-Quersickenwerkzeug kann auf leichte und präzise Weise ein Blech abgekantet und gleichzeitig mit einer Quersicke versehen werden. Diese ist zur Versteifung und Stabilisierung notwendig, zum Beispiel bei der Produktion eines Blechwinkels oder eines Blechprofils, das durch die entsprechende Querkantung versteift werden soll. In nur einem Arbeitsgang biegen Oberwerkzeug und Matrize des Quersickenwerkzeugs das Werkstück in einen 90°-Winkel und prägen die gewünschte Anzahl an Quersicken in den passenden Abständen mit ein. Auch dieses WESO-Abkantwerkzeug erhalten Sie inklusive Versuch und Werkzeugkorrektur.

Überzeugen Sie sich von der guten Verarbeitung und den vielseitigen, praktikablen Funktionsweisen unseres WESO- Etagenwerkzeugs. Das Etagenwerkzeug ist ein Multifunktionswerkzeug, das Präge-, Falz- und Zudrückwerkzeug miteinander vereint. Hiermit lässt sich ein Werkstück in einem ersten Arbeitsgang mit nur einem Hub prägen und abkanten. In einem zweiten Arbeitsgang, bei dem das Werkstück unterhalb der Matrize eingesetzt wird, kann die zuvor erstellte offene Kantung zugedrückt werden. Wie bei anderen WESO-Abkantwerkzeugen erhalten Sie auch das Etagenwerkzeug inklusive Versuch und Werkzeugkorrektur.

Mit dem qualitativ hochwertigen WESO-Z-Biegewerkzeug produzieren Sie auf funktionale und schnelle Art und Weise Z-Profile. In nur einem Arbeitsgang an der Abkantpresse biegt das Biegewerkzeug, mit präzise aufeinander eingepasstem und gehärtetem Ober- und Unterwerkzeug, aus dem Blech ein Z-Profil. Im freien Biegen lassen sich anders als beim Prägen auch unterschiedlich tiefe Z-Stufen herstellen. Das Biegewerkzeug erhalten Sie wie alle unsere WESO-Abkantwerkzeuge mit Versuch und Werkzeugkorrektur inklusive. Überzeugen Sie sich von unserem weiteren umfangreichen Angebot an Abkantwerkzeugen und Sonderwerkzeugen auf unserer Website.